Nowadays, 3D printers are more and more widely used, it is a symphony of precisely coordinated mechanical parts—and the timing pulley and belt system is one of its most essential, yet underappreciated, players. If you’ve ever wondered how your print head or bed moves so smoothly and accurately, this article will break it all down.

1. What Are Timing Pulleys and Belts?

A timing pulley is a toothed wheel that perfectly meshes with a timing belt—a flexible toothed belt. Unlike regular smooth belts, this system ensures no slippage, making motion super accurate and reliable.

Key Characteristics:

- Pulley type: GT2 (2mm tooth pitch) is most common in 3D printing.

- Belt type: Reinforced rubber or fiberglass-core belts.

- Material: Aluminum or plastic pulleys, depending on the application.

2. Their Functions in a 3D Printer

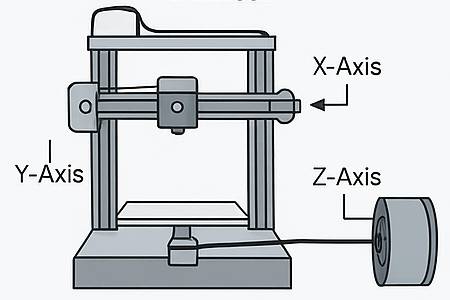

Timing belts and pulleys are found in several critical locations in most desktop FDM 3D printers:

X-Axis

Moves the print head left and right. A stepper motor with a pulley drives the GT2 belt to slide the carriage.

Y-Axis

Moves the bed forward and backward using the same pulley + belt setup.

Z-Axis (in some printers)

While many use leadscrews here, some delta or CoreXY printers use belts for vertical movement.

Extruder Drive (optional)

In certain extruder designs, pulleys transfer rotation to the filament gear for consistent extrusion.

3. Advantages of Using Pulleys and Belts

Here's why timing pulleys and belts are so popular in modern 3D printers:

| Advantage | Benefit |

| High Precision | Perfect layer placement with no slippage. |

| Lightweight System | Lower mass allows faster, quieter movement. |

| Simple Design | Easy to install, adjust, and maintain. |

| Cost-Effective | Replacement parts are inexpensive and widely available. |

| Quiet Operation | Compared to leadscrews or gears, belts are quieter. |

4. How to Maintain Timing Belts and Pulleys

While they're low-maintenance, a little care keeps them running at peak performance.

Regular Maintenance Checklist:

Check Belt Tension:

- Too loose = ghosting and backlash

- Too tight = excessive wear on bearings

Inspect for Wear:

- Look for frayed edges or stretched belts

- Examine pulley teeth for wear or buildup

Tighten Set Screws:

- Pulleys must be firmly attached to stepper shafts

- Use threadlocker to prevent loosening during prints

- Old belts stretch over time. If print quality drops and everything else checks out—it may be time for a new belt.

Replace When Needed:

Final Thoughts

Timing pulleys and belts may not be the stars of the show, but they are the backbone of precision in most FDM 3D printers. Whether you’re printing detailed minis or functional prototypes, understanding and caring for this motion system can make the difference between “meh” and “wow.”

So next time your printer glides effortlessly across its axes—thank the tiny toothed champions doing the hard work behind the scenes.

Post time: Apr 20, 2015