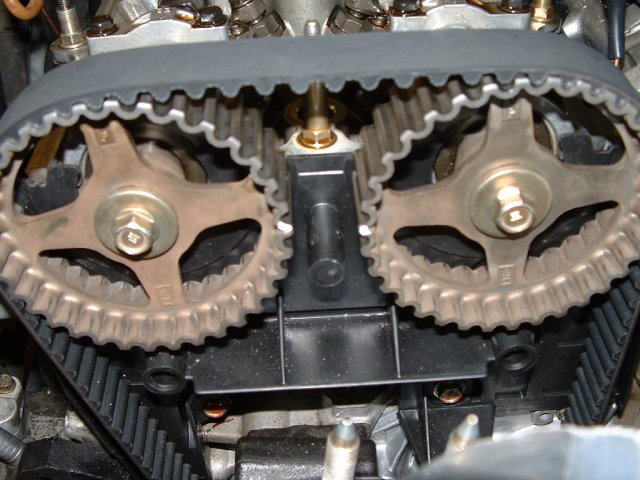

In automotive engineering, timing pulleys and timing belts form a crucial part of the engine’s synchronization system. Together, they ensure that engine components work in perfect harmony, allowing for optimal performance, efficiency, and reliability. Without this coordination, modern engines would fail to function as intended.

1. Understanding Timing Pulleys and Belts

Timing Pulley

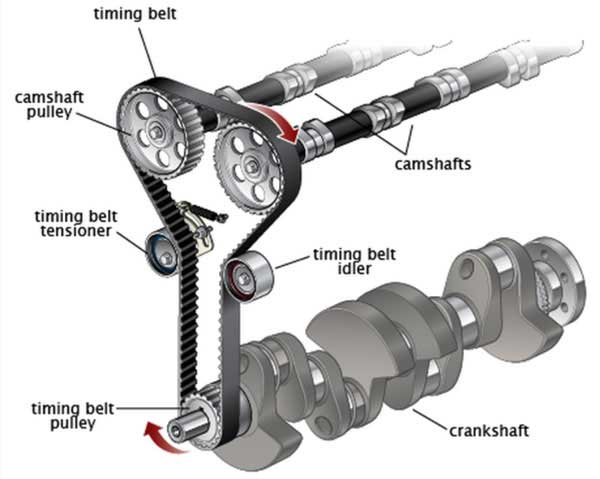

A timing pulley is a toothed wheel that engages with the teeth on a timing belt. These pulleys are typically attached to the crankshaft and camshaft(s) in internal combustion engines. Their precision design prevents slippage, ensuring accurate transmission of rotational motion.

Timing Belt

The timing belt is a high-strength rubber or polymer belt reinforced with materials like fiberglass or Kevlar. It features trapezoidal or curvilinear teeth that perfectly match the pulleys'grooves.

2. Core Function in Automobiles

The primary purpose of timing pulleys and belts is to synchronize the rotation of the crankshaft and camshaft(s). This ensures that the engine's valves open and close at the correct intervals during each piston stroke.

- Crankshaft to Camshaft Synchronization

A typical 4-stroke engine requires the camshaft to rotate at half the speed of the crankshaft. Timing pulleys maintain this exact ratio. - Valve Timing Accuracy

In interference engines, improper valve timing due to belt slippage or failure can cause pistons to strike valves, resulting in severe engine damage.

3. Key Components in the System

- Crankshaft Pulley: Drives the timing belt.

- Camshaft Pulley(s): Receives rotational force to operate intake/exhaust valves.

- Tensioner Pulley: Maintains the correct belt tension to avoid skipping or excessive wear.

- Idler Pulley: Helps guide the belt and reduce slack.

- Water Pump (in some engines): Also driven by the timing belt in many configurations.

4. Advantages of Timing Pulleys and Belts

| Feature | Benefit |

| Precision | Maintains exact timing with minimal backlash |

| Efficiency | Lightweight components reduce engine load |

| Noise Reduction | Quieter than metal timing chains |

| Low Maintenance | Requires replacement but generally needs little maintenance |

Timing systems using pulleys and belts are more common in smaller and lighter engines, especially in passenger vehicles, due to their quiet operation and efficiency.

5. Maintenance and Replacement

Regular inspection and timely replacement are crucial. Most manufacturers recommend replacing the timing belt between 60,000–100,000 miles (96,000–160,000 km), depending on the vehicle.

Signs of a Failing Timing Belt:

- Engine misfires

- Ticking or clicking noises

- Oil leaks near the timing cover

- Check engine light or complete engine shutdown

Neglecting timing belt maintenance can result in catastrophic engine failure.

6. Innovations and Evolving Designs

- Dry Belt Technology: Some newer engines use dry belts that operate outside the oil system, improving longevity and reducing contamination.

- Variable Valve Timing (VVT): Advanced timing pulleys can now adjust the phase angle dynamically, enhancing performance and fuel efficiency.

7. Conclusion

The partnership between timing pulleys and timing belts plays an indispensable role in the operation of internal combustion engines. By ensuring precise timing of valve and piston movements, they contribute significantly to engine performance, fuel economy, and overall vehicle reliability.

As automotive technology progresses, timing systems continue to evolve—yet their core purpose remains unchanged: to keep your engine running in perfect rhythm.

Post time: May 02, 2015